Washing area

The sprayer washing area must be watertight and properly sized to collect phytosanitary effluents, separating them from rainwater and other washing water. It must include a screening system to retain solids and devices to separate water, such as valves or guillotines. Phytosanitary effluent must be treated or collected by an approved body, while various types of wash water must undergo pre-treatment to eliminate hydrocarbons.

The washing area: to specifically recover phytosanitary effluents

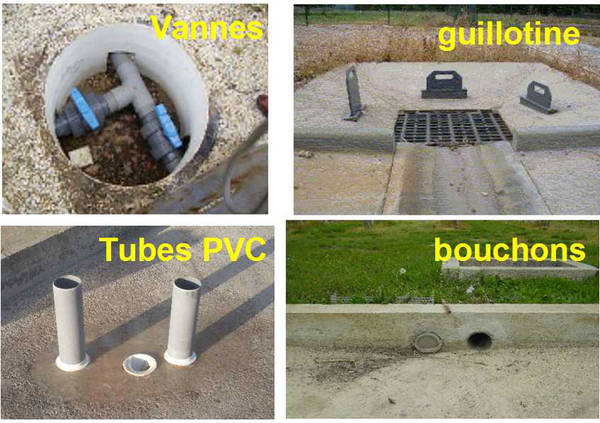

The sprayer washing area must be specifically designed to collect water contaminated by plant protection products. This means that you need a well-sized, watertight area with a slope (2% minimum) that sends all the water to a manhole to separate rainwater and other washing water from plant protection effluent. There are several systems that can be used to achieve this separation. There are often manual quarter-turn valves or plugs. But there are also more practical methods, such as guillotine systems or PVC pipes. Make sure that the system for diverting the channels is easily accessible to avoid any risk of error.

Regarding the position of the manhole, it can be in the middle of the wash area (diamond-shaped area) or on one side of the area, which allows easier access.

It is important to consider installing a screening system at the manhole. The equipment likely to be washed in the wash area is often dirty, full of soil or leaves in particular. It is therefore important to retain most of these solids to prevent the outlets from clogging. If the grape harvesting machine is also washed in the same area, a third specific channel must be provided for this water.

What happens to the waste water?

Typical diagram of a washing area with 3 outlets

- Plant protection effluent outlet Crop

- .

- At the rainwater and miscellaneous washing outlet The

- .

- At the possible outlet for washing water from the grape harvesting machine This is

Designing the washing area: questions to ask yourself

- Before building a wash area, it's important to ask yourself a few questions:

- Is my project located in a water catchment protection zone, near a watercourse or in a sensitive area?

- Is my project close to the product storage area?

- Are there any plans for a collective area nearby?|

- ||

- What is the size of the largest machine that will be washed at my site?

- What is the average volume of phytosanitary effluent to be managed over a treatment campaign? And in particular, what is the volume of water used to wash each machine?

- For private wineries, and if a grape harvesting machine is washed on the farm: is it possible to connect my washing area to the collection and treatment system for my winery effluents?

Experiment

See the list of experimentsSee more - Optimising water use and reducing effluent - 2020

- Designing your wash bay - 2011

- Designing and organising your carwash - 2010

- Field washing - 2010

- Collective washing areas, feedback - 2009

- All you need to know about sprayer filling and washing areas - 2008

- Sprayer rinsing in the field: benefits and feasibility - 2005