Safety equipment and PPE

Wine production exposes workers to specific risks associated with fermentation, confined spaces, chemicals, working at height and working in isolation. Preventing these hazards requires the use of appropriate safety equipment, including gas detection, personal protective equipment (PPE), fall prevention devices, ventilation systems and emergency response resources. The aim is to guarantee the safety of operators while ensuring the continuity of cellar activities.

Context and safety issues in wineries

Wine-making activities expose workers to specific risks linked to:- alcoholic fermentation (massive release of CO₂)

- confined spaces (vats, pits, cellars)

- chemical products (disinfection, treatments, CIP cleaning)

- working at height (vat room, walkways, presses)

- isolated work

Prevention is based on a combination of several factors:

- organisational measures

- appropriate ventilation of premises and spaces

- risk detection

- individual and collective protective equipment (PPE)

Regulatory obligations

Regulations require employers to assess and prevent the risks associated with hazardous atmospheres and working in isolation.Prevention organisations insist on three pillars: capture at source, appropriate ventilation and reliable detection. These measures are essential to reduce exposure to hazardous gases.

Risks and dangers

It is estimated thatone litre of wine produces around 50 litres of CO₂ during alcoholic fermentation.This gas, which is heavier than air, is released into the atmosphere and forms a 'disk' above the vats and then accumulates on the floor, especially in poorly ventilated areas of the winery.

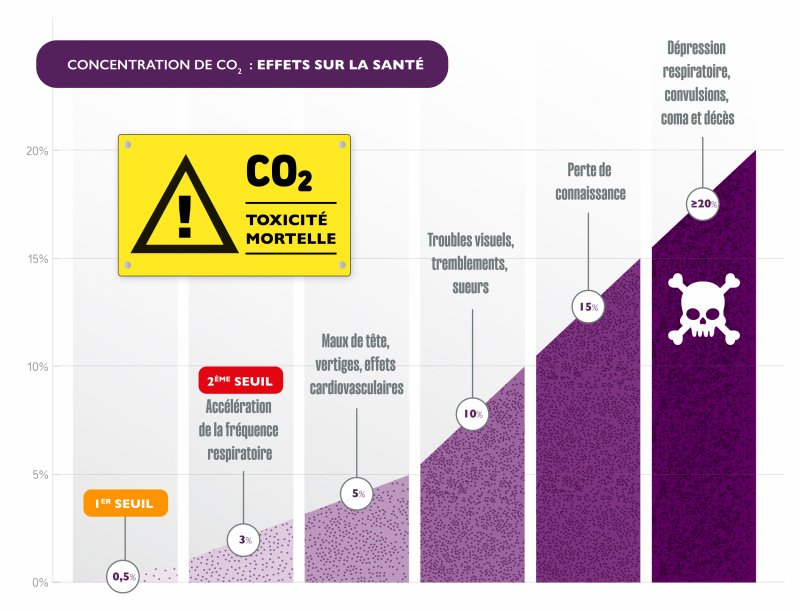

The effects on health

- From 3% CO2 in the air, there is an acceleration of the respiratory rate.

- From 5%: fatigue, headaches, irritability, impaired concentration and alertness.

- From 10%: severe symptoms such as visual disturbances, tremors and sweating.

- From 15%: onset of critical threshold with loss of consciousness.

- From 20%: critical threshold with respiratory depression, convulsions, coma and death.

Dramatic accidents, including cases of fatal asphyxiation, have been recorded, particularly when opening cellars or working in tanks.

C02 concentration and health effects

Gas detection

While carbon dioxide (CO₂) is the best-known gas in viticulture, particularly during alcoholic fermentation, it is not the only potential hazard. Staff can also be exposed to:Carbon dioxide (CO₂)

- Produced during fermentation

- Odourless, colourless gas

- Heavier than air → accumulates in low areas

- Risk: rapid asphyxiation without warning signs

The candle test

A practice that is still widespread but formally inadvisable: the flame remains visible well above lethal CO₂ thresholds, and only reflects the absence of oxygen, not the safety of breathable air. An educational experiment has shown that a candle can continue to burn when the detectors are already measuring dangerous levels, confirming the ineffectiveness of this method.Other possible gases

- SO₂ (sulphur dioxide)

- H₂S (hydrogen sulphide)

- Gases linked to maintenance: solvents, chemical vapours or oxygen-depleted atmospheres

- CO (carbon monoxide): from poorly ventilated heat engines, boilers or heating equipment

- Oxygen deficiency (O₂): due to displacement of air by other gases or insufficient ventilation

Types of detectors

Accurate detection of CO₂ is essential: only specialised sensors can reliably measure CO₂ levels. Connected gas detection enables real-time monitoring of the atmosphere in high-risk areas. Thanks to connectivity, it brings real added value to prevention.Portable personal detectors

- worn on the belt or torso

- continuous measurement

- immediate audible/visual/vibrating alarm if threshold is exceeded

- simultaneous detection of several types of gas

- automatic data transmission to a supervision platform.

- remote display of risk situations.

- history and traceability of exposure.

Fixed detectors

They have the same features as portable models, except that they monitor larger work areas and can be integrated into the ventilation system to trigger action if necessary.

All these features make it possible to anticipate incidents and intervene quickly, even when the worker is isolated.

Parameters that can be measured: O2, CO2, SO2, H2S, CO, etc

Best practice

- regular calibration (6 to 12 months) to guarantee measurement reliability

- bump test before use

- staff training

- defined evacuation procedure

Protection of lone workers (PTI / DATI)

Situations concerned

The following is a list of work configurations that may give rise to risks for isolated workers and require individual protection using modern PTI or DATI certified equipment:- employee working alone and autonomously in a winery

- tank cleaning

- maintenance in isolated areas

- working at night or outside normal working hours

PTI/DATI devices

PTI = Protection for lone workersDATI = lone worker alarm device

Key functions of these modern alert systems

- voluntary alarm by the isolated person in the event of respiratory distress or a fall

- detection of absence of movement

- detection of a fall

- location (GPS or radio) of the person in difficulty

- transmission of alerts to a monitoring centre, emergency services or a manager's telephone number

The equipment comes in the form of a PTI/DATI badge, secure smartphone, watch or dedicated box, and the various functions listed above can be combined on the same device.

This system requires an intervention procedure, designated people to receive alerts and periodic system tests.

Respiratory protection equipment

Respiratory risks in wineries

On a daily basis, in a winery, employees are confronted with various respiratory risks, even outside the winemaking period, for example:- use of SO₂ (irritant and toxic)

- vapours from disinfectant products when cleaning the vat room

- oxygen-poor atmosphere during vinification

- CO₂ in the vats during the fermentation phase

Types of respiratory protection equipment

What masks are used?

Disposable filter masks FFP2 (dust, aerosols) and FFP3 (reinforced protection) are not approved for these types of risk.However, masks with filter cartridges (A,B,E,ABEK) and self-contained breathing apparatus (SCBA) are suitable and compulsory for use in unknown and O2-depleted atmospheres.

Rules of use

There are a few rules to follow to ensure proper operation:- leak test

- periodic replacement of cartridges

- dry storage

- compulsory training

Ventilation of confined spaces

Every winery almost always includes one or more confined spaces that are difficult to ventilate. This could be a fermentation tank, a vat or reception pit, an underground network or a windowless room.When the level of CO₂ exceeds 0.5%, it is recommended touse an air extractor (centrifugal or helical) fitted with a variator to adjust the air flow as required. An intervention protocol (fan installation, ventilation duration, equipment required, presence of a supervisor, etc.) must be formalised and strictly followed. CARSAT also recommends systematic forced ventilation in high-risk areas.

Objectives for combating O2 deficiency

- dilution of CO₂ by aeration

- oxygen supply

- evacuation of chemical vapours

How do you ventilate?

Ideally integrated into the design of the winery, prevention should aim to limit gas stagnation zones and facilitate efficient air renewal. Solutions exist, either by :Natural ventilation

- High and low openings , but insufficient only during intense fermentation

Mechanical ventilation (recommended)

- Air extractors

- Forced ventilation

Procedure for entering confined spaces

- atmospheric analysis

- prior ventilation

- appropriate PPE

- external supervisor

- emergency plan

Chemical protection equipment

Risks associated with cleaning and disinfecting products

In oenology, this is usually equipment linked to the risks of using cleaning or disinfecting products, such as :- caustic soda

- cleaning acids

- disinfectants

- sulphur dioxide solutions

Recommended personal protective equipment

The aim is essentially to protect the whole of the human body during any handling with PPE, i.e. :- type 3 or 4 chemical suit (liquid spray)

- pVC apron

- waterproof clothing

- nitrile, neoprene or butyl gloves

- goggles

- face shield

- non-slip chemical boots

Fall arrest equipment

Causes of falls

In a wine storehouse, there is always a risk of falling, and there can be many reasons for this:- tank walkways

- wet metal staircases

- working on presses

- cleaning at height on ladders or stepladders

Fall arrest systems

There are preventive solutions to prevent falls:Priority collective protection

- guardrails

- secure platforms

- fixed lifelines

Individual protection

- eN 361 fall arrest harness

- lanyards with energy absorber

- automatic fall arresters

- certified anchorage points

Good practices are also essential to ensure the safety of employees, including a compulsory annual inspection, training for working at height and the implementation of a suspension rescue plan.

Summary of recommendations for winegrowers

By integrating connected gas detection and lone worker protection, winegrowers and winemakers now have a comprehensive approach to safety. This combination makes it easier to anticipate risks, protect teams and ensure the long-term safety of cellar and winery activities.| Prevention | Recommended actions |

| Design of the winery |

|

| Capture and ventilation |

|

| CO2 detection |

|

| Work organisation and training |

|

| Equipment maintenance |

|

Prevention in a company is based on equipment, but also and above all on an effective strategy combining :

- risk assessment

- regular staff training

- appropriate signage

- equipment maintenance

- emergency procedures

- safety culture in operation