CO2: detection / capture and processing

Carbon dioxide (CO₂) is a natural by-product of alcoholic fermentation, generated when yeast transforms grape sugars into alcohol. One litre of wine produces up to 50 litres of CO₂, a colourless, odourless gas that is heavier than air, which accumulates on the floor and can cause serious or even fatal accidents if there is no ventilation. Asphyxiating at low concentrations, it represents a major risk for workers in the cellars. In addition to its impact on health, CO₂ is a greenhouse gas that is harmful to the environment. Its management is therefore a crucial prevention and recovery issue.

Carbon dioxide (CO₂) in wine cellars

Origin of carbon dioxide

CO₂ is a natural by-product of alcoholic fermentation, where the sugars in the grapes are converted into alcohol by the yeasts generating large quantities of carbon dioxide. It is estimated that a litre of wine produces around 50 litres of CO₂ during alcoholic fermentation.

This gas, which is heavier than air, is released into the atmosphere and forms a 'disk' above the vats and then accumulates on the floor, especially in poorly ventilated areas of the winery

Risks and dangers

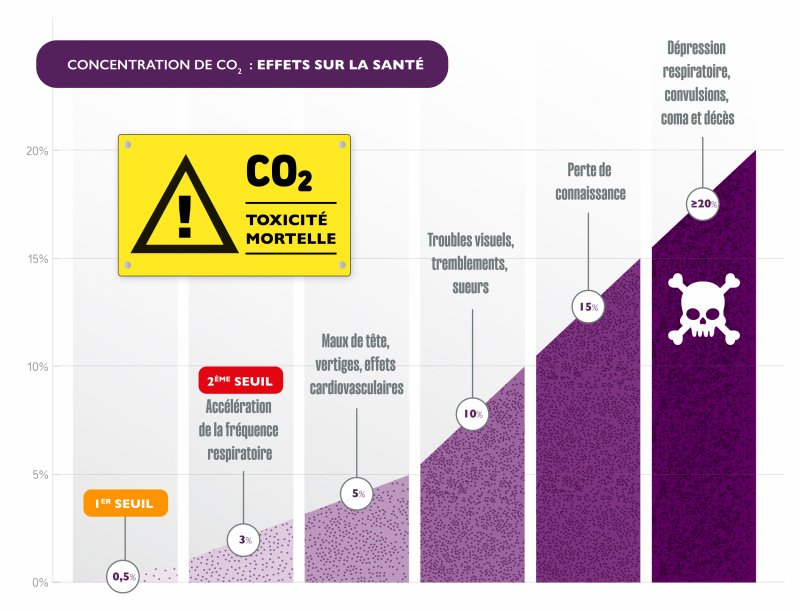

CO₂ is odourless, colourless and asphyxiating and therefore potentially lethal.The effects on health

From 3% CO2 in the air, there is an acceleration of the respiratory rate.From 5%: fatigue, headaches, irritability, impaired concentration and alertness.

From 10%: severe symptoms such as visual disturbances, tremors and sweating.

From 15%: onset of critical threshold with loss of consciousness.

From 20%: critical threshold with respiratory depression, convulsions, coma and death.

Dramaticaccidents: there have been cases of fatal asphyxiation, particularly when opening cellars or working in tanks.

Accumulationat low levels: CO₂ stagnates in low areas, making interventions in pits or basements difficult particularlymen

CO2 concentration and health effects

Effects on the environment

Carbon dioxide is harmful to the environment because it is the main greenhouse gas.Prevention and concrete action for safety in the winery

Principal actions

- Capture at source

- Installing an evacuation system at the top of the vats, connected to the outside via pipes, allows the CO₂ to be directed out of the winery. This keeps exposure below the VLEP.

- It is important to plan for these installations when designing or extending the winery, in consultation with the vat room manufacturers.

- Mechanical ventilation |

- When the CO₂ level exceeds 0.5%, it is recommended to use an extractor (centrifugal or helical) fitted with a variator to adjust the air flow rate as required. An intervention protocol (fan installation, ventilation duration, equipment required, presence of a supervisor, etc.) must be formalised and strictly followed.

- CARSAT also recommends systematic forced ventilation in high-risk areas, as well as a CO₂ detector

- Reliable detection

- It is crucial to install CO₂ detectors, portable or fixed, with infrared cells, to continuously measure the concentration in the air. Fixed detectors can be coupled to the ventilation system to automatically switch on extraction as soon as a threshold is exceeded. Empirical methods (candles, lighters, etc.) must also be avoided.

Other solutions

- Human organisation

- Give preference to working in pairs / operator for better monitoring and ensure training, written protocols and the implementation of an external monitoring system.

- Capture and reuse of CO₂ |

- New equipment now makes it possible to capture, purify, store and reuse fermentative CO₂. This approach contributes to cellar safety, reduces the carbon footprint, and enhances the value of a natural and free resource.

Conclusion

The CO₂ produced by fermentation represents both a real and invisible danger to health, but also a valuable resource. The combination of prevention (capture, ventilation, detection, protocols, training) and recovery (industrial or small-scale conversion, internal use, filtration, storage) offers a comprehensive approach: making teams safe, reducing the carbon footprint and creating new economic outlets.