Capture and conversion of CO2

La fermentation alcoolique produit naturellement du dioxyde de carbone (CO₂), jusqu'à 8 kg par hectolitre de vin, un gaz souvent rejeté dans l'atmosphère. Pourtant, son accumulation dans les chais représente un danger réel pour les travailleurs et une perte de ressource. Grâce aux innovations récentes, il est désormais possible de capter ce CO₂ à la source, de le purifier et de le valoriser. Cette démarche améliore la sécurité, réduit l'empreinte carbone et ouvre la voie à une économie circulaire dans le secteur viticole. Le CO₂ devient ainsi un levier de performance et de durabilité.

Presentation

During the alcoholic fermentation process, yeast transforms sugar into alcohol and produces carbon dioxide CO₂ (up to 8 kg per hectolitre of wine), a natural step but energetically marked by a significant emission of carbon dioxide released into the atmosphere. In wineries, this accumulation of CO₂ can be dangerous for staff (risk of asphyxiation) and represents a missed opportunity when this gas is simply evacuated. Recently, technological innovations have made it possible to capture this CO₂ at source so that it can be recovered in a variety of ways, forming part of a circular economy and environmental sustainability approach.

The benefits of capturing and recovering CO₂

Staff safety

High concentrations of CO₂ in cellar air are dangerous (risk of asphyxiation). Capture at source - at the top of fermenting vats - reduces this risk by evacuating the gas before it accumulates in the lowest areas of the cellar.Reducing the carbon footprint

By reusing the captured CO₂, wineries can reduce their consumption of fossil gases (industrial CO₂) while mitigating their environmental impact.Resource savings and operational efficiency

Improved cleaning

Water enriched with CO₂ (2 g/L) improves wetting power, cleans better and reduces water consumption by 20-70% depending on the case.Tank inerting

CO₂ is denser than nitrogen, creating a more stable protective "curtain" to prevent oxidation in the vatsOptimisation of oenological processes: injecting CO₂ under the cap of marc (pumping over, punching down) promotes better extraction and homogenisation, with a gain in efficiency.

Adding value to by-products

The CO₂ captured can be transformed into marketable products:- Sodium or potassium bicarbonate, for use in cosmetics, detergents, pharmaceuticals, agriculture, spiraline, etc.

- Dry ice or snow for inerting, transport, harvesting, pressing, etc.

Advanced oenological innovations

- Alcohol reduction: under development, injecting fermentary CO₂ could reduce alcohol by 0.5 to 2°vol.

- Recovering aromas: a recondensation column makes it possible to recover the aromas entrained by the CO₂, offering unprecedented sensory possibilities.

- Harvest protection: in fine harvesting, CO₂ (in the form of dry ice) protects the berries from oxidation right up to the press.

- Compression-expansion for transport: pockets of CO₂ in the pipes used to transport the grapes reduce the mechanical shattering of the berries while protecting them from oxidation

Circular economy and sharing platform

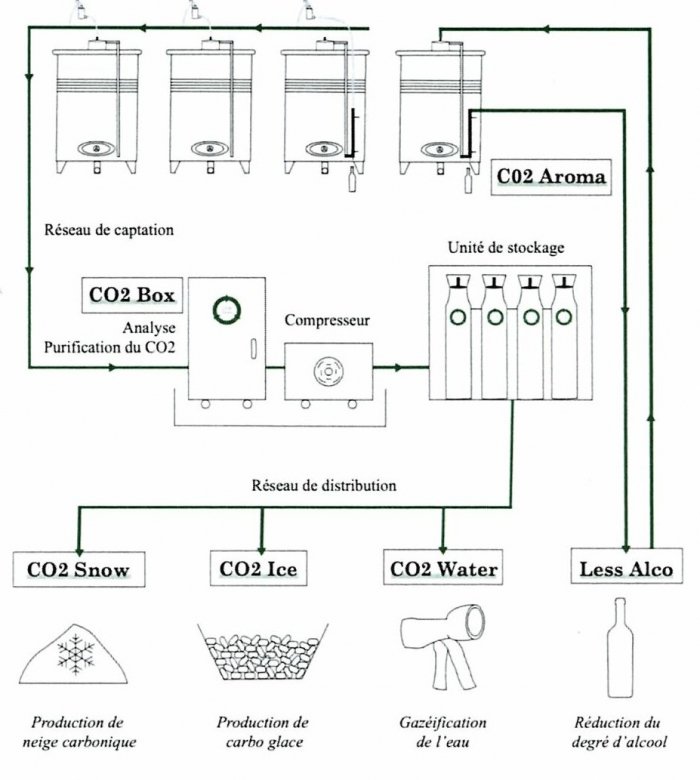

Buying/selling platforms to pool surplus biogenic CO₂ between estates, encouraging a collective dynamic.Operating principle

Capture of CO₂

The carbon dioxide produced during fermentation is collected directly from the outlet of the tanks (chimneys or hatches), via piping connected to the bungs, hatches or tank tops. The gas circulates in the network by overpressure to a storage module. Quite simply, the gas can be reused immediately in adjacent vats for inerting, extracting marc or stirring lees or bourbes, while the surplus is kept for later use. In this case, the gas can then be filtered (to remove suspended particles and yeast), dried to reduce moisture, and sometimes sterilised to guarantee its microbiological purity. Once purified, the CO₂ is compressed (from 10 to 200 bars depending on the system) and then stored in a pressurised tank in gaseous or liquefied form, ready to be used internally or sold or transformed into dry ice/snow. Some equipment can also be used to chemically transform CO2 into sodium or potassium bicarbonate, which is then used in the vineyards to protect plants or as a detergent. Sodium bicarbonate is a basic substance that can be used in viticulture without prior authorisation, provided it is of food-grade quality, by winegrowers who produce it - it is included on the European list of basic substances, and self-use can be envisaged in this context - unlike potassium bicarbonate, which is a biocontrol product and therefore subject to approval.

Valuation according to use

They are used for a wide range of purposes:

- Inerting vats, presses, grape harvests and miscellaneous operations

- Reassembly, stirring with controlled injection

- Gasification of wines

- Cleaning with carbonated water

- Bicarbonate for sale or internal use

- Dry ice, transport inerting, grape protection

- Alcohol reduction, aroma recovery

- Recovery from third parties (food industry, etc.)

Conclusion

The capture and recovery of fermentative CO₂ in winemaking cellars represents a major innovation at the crossroads of safety, ecology and economy. Thanks to recent and innovative technologies, CO₂ is ceasing to be a problematic gas and becoming a valuable resource - used for inerting, cleaning, inerting, cooling, aromatic extraction, dealcoholisation or even marketed in the form of bicarbonate.Numerous examples from wineries in Alsace and Bordeaux, among others, show that this transition, which is both profitable and virtuous, is now accessible to the wine industry.